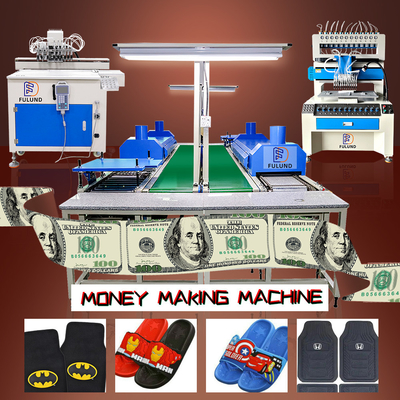

Factory Energy Saving Full Automatic Car Mats Making Machine Rubber Mat Produce Line Popular In Many Countries

This production line is used for produce multicolor 3D skipprrof and waterprrof PVC mat for all kinds of car and motobike ect.

3.Hight Production: 1500pcs/day.

Pvc car mat Product information:

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()