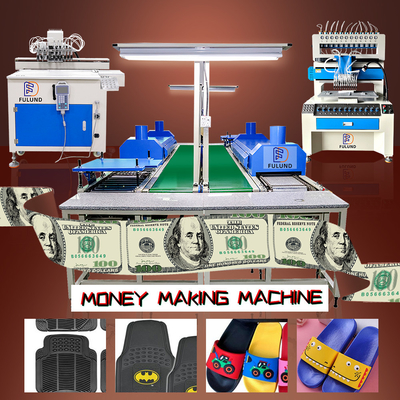

Supply Automatic Car Mat machine making running shoes pvc injection shoe making machine Produce Line

This production line is used for produce multicolor 3D skipprrof and waterprrof PVC mat for all kinds of car and motobike ect.

3. Hight Production: 1500pcs/day.

Product feature and application

1. Precise control system,automatic production,human caused errors can be avoided,insure production pass rate.

2. Labor cost saving,just need 2-3 workers in whole processing.

3. Easy operation,worker can make acceptable product after a short-term training.

4. high production,1500pcs/day,24 hours running smoothly.

5. Automatic identification system,can make 100 different kinds of mat at same time

6. Contingency productions system,each unit can be independent control,according to product to adjust.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()